Technical Description

EVS 1500 and EVS 1500LF

System Description

The Solder Recovery System EVS 1000 to 9000 range of equipment provides a closed environment system for the recovery of solder from the solder dross produced during the wave soldering process.

The New EVS 1500 is a smaller, lighter version of the popular EVS 8K and EVS 10K Range with all of the recovery performance of the standard and lead-free solder units. The smaller size and footprint help reduce the cost, but still provide a capacity of 10lb/5kg of lead dross and 8lbs/3kg of lead free dross, giving a rapid payback and impressive return on capital (ROI).

The very quick cycle time and manoeuvrability of this new machine will appeal to all customers who regularly de dross, use nitrogen or use 1 or 3 waves.

With the increasing cost of solders and labour around the world the EVS 1500 is being installed at manufacturing facilities by customers looking to save money and improve their process.

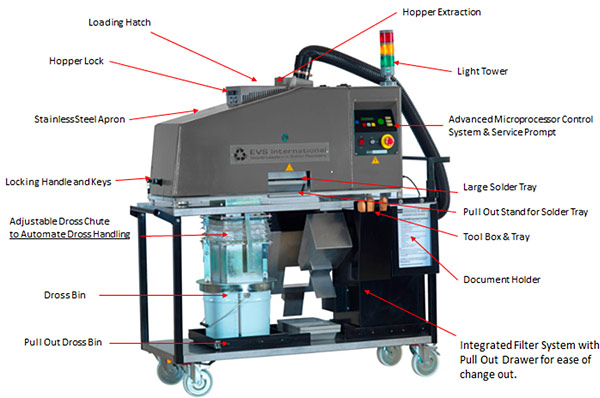

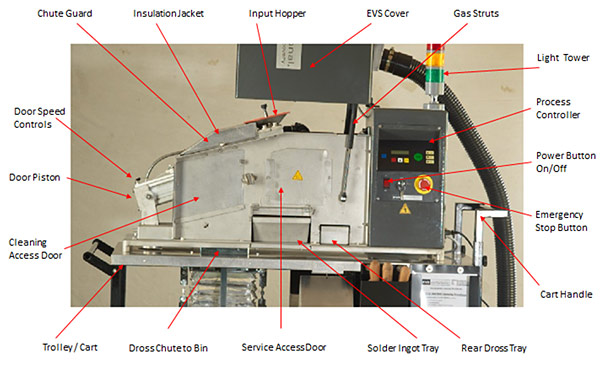

The EVS 1500 normally bought as a system comprising of a trolley/cart, a drop through chute for the automatic collection of spent solder dross/waste and an integral standalone filtration unit consisting of a multistage filter and a high flow fan. This system is designed to be a stand alone unit which can operate at the convenience of the user company, running off a single phase power supply without the need for external extraction or ducting of fumes exhausted from the process.

This system is designed for use with hot solder dross. The double patented product and process uses heat, pneumatic pressure and magnetic current to extract the solder from the dross at temperature. The solder collected from the process should be returned once cooled to the same solder bath the dross was taken from. Please ensure that the solder is returned to the original bath to maintain integrity of your solder analysis. The EVS heats the loaded dross to the preset operating temperature. Pressure is then applied via the pneumatic cylinder in order to compress the dross loaded into the machine. This process enables the majority of retained solder in the solder dross to be extracted. The spent dross and impurities are deposited from the operating chamber into the dross bucket via the dross chute as one automated process. No operator involvement is required subsequent to the pressing of the start button.

The machine processing cycle is performed automatically. All user-accessible parts of the system are monitored and electrically interlocked to ensure correct positioning during operation and to provide safe and reliable operation.

Forced air extraction within the machine ensures that a negative pressure is maintained and any gaseous material within the dross entering into the air passes through a multi-stage filter, which removes particulate matter down to 0.6 micron and neutralises the gases via an impregnated carbon gas filter media.

The machine carries the CE approval marking.

The system should be assembled on the trolley as per assembly instructions. On mounting the Solder Recovery System on the top trolley shelf open the cover and check all screws and fixings are in place and tightly retained. Check for any loose wires, any loose nuts or bolts particularly on the pneumatic fixing points, the door, the bridge plate and chamber retention points and any electrical and earthing points, and if found please report to your equipment supplier or local representative.

Features

The EVS 1500 offers the following features as part of the machine:

- 3-5KG/6-11 Lbs capacity for hot dross

- Automated collection of spent dross

- Integral treatment of fumes and vapours emitted from process are handled by a multi-stage filtration system which creates negative internal pressure within the EVS and when loading with dross

- Solder tray lock preventing removal of solder tray during process

- Loading Hopper Lid Lock to prevent accidental loading during cycle

- Solder tray air knife to accelerate cooling of recovered solder

- Dross chute air knife to keep dust and fumes in the dross bin/bucket.

- Coded fail safe proximity switches used on both the solder collection tray and the integral loading hopper

- Adjustable dross chute to automate dross handling into dross bin

- Increased heat capacity allowing a faster warm up time

- Integral electronics including liquid crystal display giving operator information on the machine status and status of current cycle and service prompts

- Display feedback of possible cycle faults via the liquid crystal display

- Simplified heat control via one thermocouple with second Thermocouple on duplicated safety system

- Simplified wiring directly from the machine outputs to the connector blocks on the circuit board

- Improved door seal arrangement to enhance door integrity during recovery process

- Rear dross chute enabling easy or automatic removal of dross from behind the piston during cycling simplifies maintenance and cleaning

- Light Stack both warning and functional.

Integral Air Filtration and Extraction – Stand Alone Filter (SAF)

The fume extraction unit draws a current of air across the heating chamber, and filters this air before returning it to the atmosphere. This process removes gaseous particulate, which may be produced during the solder recovery process or during the dross ejection phase of the process.

As details under Routine Maintenance, it is important that the input slots and the extraction port are kept clear, as any reduction in the rate of airflow will affect the performance of the equipment.

1. SPECIFICATIONS

The manual relates to the EVS 1500.

| SYSTEM |

EEVS 1500/1500LF Solder Recovery Machine

EVS Trolley / Cart

Stand Alone Filter

Drop Through Hopper & Chute

Hopper Extraction Hood

|

| DIMENSIONS |

Metric |

Imperial |

| Machine |

Width |

300mm |

11.8ins |

| |

Height |

530mm |

20.8ins |

| |

Length |

900mm |

35.4ins |

| |

Weight |

65kg |

143lbs |

| Trolley/Cart |

Width |

450mm |

19.6ins |

| |

Height |

650mm |

25.6ins |

| |

Length |

900mm |

35.4ins |

| |

Weight |

45kg |

99lb |

| Std - Stand Alone Filter (SAF) 5000-200 |

| |

Width |

320mm |

12.6ins |

| |

Height |

525mm |

20.7ins |

| |

Length |

320mm |

12.6ins |

| |

Weight |

30kg |

67.2lbs |

| Option - High Solids Fluxes Only (SAF) 5000-200-HS |

| |

Width |

380mm |

15.0ins |

| |

Height |

590mm |

23.3ins |

| |

Length |

380mm |

15.0ins |

| |

Weight |

40kg |

88.2lbs |

| CAPACITY |

|

|

|

| Dross Chamber |

EVS 1500 |

5 kg |

11 lbs |

| |

EVS 1500LF |

3 kg |

6 lbs |

| Solder Tray |

EVS 1000 |

5 kg |

11 lbs |

| |

EVS 1500LF |

5 kg |

11 lbs |

1.1 POWER REQUIREMENTS

Minimum 210 volts x 5.5amps = 1.1kva

Maximum 240 volts x 5.0amps = 1.2kva

Single Phase 50 / 60 hz

Electrical consumption 1200 Watts peak

NB: The unit Must be earthed at all times when in operation

| AIR PRESSURE |

1350kPa |

6 Bar/88 psi |

| Maximum Air Consumption |

0.12m3/min |

4ft3/min |

NB: Only during compression and cooling cycle 6 to 10 minutes approximately.

OPTIONS

Spare Solder Trays

Spares Kits

Filter Kits

High Solids Filter

|

Optional for multiwave dedrossing

Levels L1, L2, L3

Levels F1, F2, F3

New HS High Solids Fume Extraction

|

CONTROLS

Power on

Start button

Cycle Light

Ready Light

Auto/Manual Button

Mode Button

Cover Lock ) Indicators

Hopper Door ) with automatic

Tray Sensor ) fail safe cut out |

LCD Display Showing:-

Temperature

Cycle time elapsed

Cycle count

Fault status

Maintenance status

WARNING AND FUNCTIONAL LIGHT STACK |

SAFETY FEATURES

Fail safe cut out switches for EVS and SAF

Emergency Stop

Automatic over temperature cut out

Fuse protected circuits

Additional temperature control for H-Bands

Solid State Relays

Integral Hopper Lock

Solder Tray Lock

Automatic Cover Open Cut Out

|