Altech UEC SA Discovers EVS International’s Secret to Improving Efficiency

JSE-listed Allied Technologies Limited (Altech), is a leading South African multi-billion rand high-technology group that operates in the Telecommunications, Multi-media and Information Technology (TMT) environments, with a strong focus on convergence in the TMT environment, with a view to achieving global prominence. Its strong presence in a variety of industry segments and high level of recurring income provides robust cash flows for the business and reduces the effects of economic cycles. Altech’s areas of focus - the South African and Australian digital migration programmes and the company’s East African data centre and network expansion activities, the ICT sector’s convergence opportunities and the expansion of our annuity income base - all bode well for future prospects and growth.

Forecasting solder metal prices in waste streams

According to the RoHS directive (www.rohs.gov.uk), “the Directive aims to restrict certain dangerous substances commonly used in electronic and electronic equipment. Any RoHS-compliant component is tested for the presence of Lead (Pb), Cadmium (Cd), Mercury (Hg), Hexavalent chromium (Hex-Cr), Polybrominated biphenyls (PBB), and Polybrominated diphenyl ethers (PBDE). For Cadmium and Hexavalent chromium, there must be less than 0.01% of the substance by weight at raw homogeneous materials level. For Lead, PBB, and PBDE, there must be no more than 0.1% of the material, when calculated by weight at raw homogeneous materials. Any RoHS compliant component must have 100 ppm or less of mercury and the mercury must not have been intentionally added to the component.”

Solder material today is based primarily on tin (Sn), Silver (Ag) and Copper (Cu). Tin is the primary metal base (96,5% to 99%) and analysis in this case is based on tin only, as the other elements constitute less than 3% aggregated content.

Due to oxidation while in the molten process stage, solder dross is formed, forming Tin Oxide which has then to be removed from the solder baths, as they are impurities and cause inefficiencies. This is the point of intervention, where commercial value is pursued in extracting the maximum value from this waste by-product.

Wikipedia defines dross as “a mass of solid impurities floating on a molten metal. It appears usually on the melting of low-melting-point metals or alloys such as tin, lead, zinc or aluminium, or by oxidation of the metal(s). It can easily be skimmed off the surface before pouring the metal into a mould or casting flask. ”

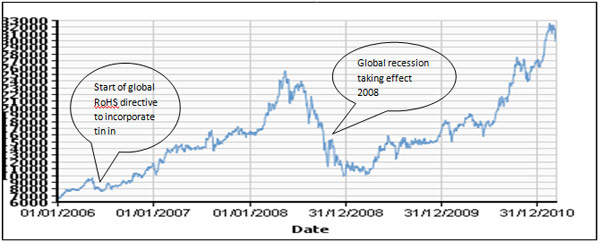

The high degree of variability in the month to month volume of dross, can be attributed to some production output fluctuations, which usually vary in the region of 10 to 15%. Other factors are unstructured handling of the dross account and timeous disposal. This results in out of period accounting, as there are delays or inaction by waste management personnel. Also, delays can prove useful, given that the price of tin has shown a 60% increase in a year. Later dispatches of dross will attract higher spot rate prices for the commodity.

Forecasting of virgin metal prices is subject to multiple subjective influencing factors and other consequential costs. Cash prices for dross are a significant factor of the virgin metal price, but are loosely tracked.

These subjective influences include:

Crude oil price, as the cost of transport of metals is subject to fuel prices. These metals are often sourced on global markets and subject to supply chain infrastructure costs from foreign ports of embarkation.

Market demands, especially as has been witnessed in the global recovery since 2009, and the steep price ramp for tin, which is a principal ingredient in global electronics.

Coking coal prices, as high grade coal is used in power generation, for which there is great demand, thus causing high coal prices and electricity prices, in addition to direct input costs for metal processing.

Judging by the reducing trend for dross sales, more innovative interventions need to be applied so that waste streams are cost self-sustaining, or be swapped with better recovery systems, installed in-process. In addition, the differential creep between raw material cost to dross prices is divergent, implying we are getting less per kg.

PRICE ANALYSIS: PERIOD JAN 2006 TO DEC 2010

Source: www.lme.com/tin_graphs.asp

PRICE ANALYSIS: PERIOD JAN 2010 TO DEC 2010

Source: www.lme.com/tin_graphs.asp

Wave Soldering has been around for a long time and although it has become more effective and more efficient as a process, one thing hasn't changed much, in that most solder machines generate a high amount of dross. In fact, on average some 75% of the solder in the bath oxidizes over time to become dross which has traditionally been dumped into a bucket and disposed of as scrap.

In the past, reducing the solder dross has not been a high priority for most busy production engineers. And over the years its low level in the pecking order has resulted in minimum attention paid to the environmental issues of lead oxides from the solder and the financial consequences of large amounts of untreated dross.

Metal dealers and solder suppliers have however a different perspective. They know that dross is almost entirely made up of pure solder and if they can recover it, they can cheaply reprocess it and sell it back to users. As only 25% of what they sell ends up on the boards at any one time they can effectively sell the same solder four times over.

The task of de-drossing is carried out with varying degrees of thoroughness. Those in a hurry often put as much solder as dross into the scrap bucket. On the other hand, those who have time to spare, may manually squeeze the dross through a perforated ladle, breaking down the crusty oxide coating to release some of the trapped solder back into the bath, before placing the residue into the bucket. However, even this process which extends the wave down time still results in a minimum amount of solder being recovered and takes vital time away from production.

Health and safety regulations however, are continually pushing back the levels of previously acceptable practices to improve working conditions. When dross is being manually squeezed there is a greater chance that these dangerous substances can be released into the workplace and particularly affects the operators squeezing the dross.

When good environmental practice has an instant payback

Altech had a number of objectives in mind when identifying an effective method of solder dross recovery. It was vital that these objectives were in line with the company’s policy of continuous improvement while minimizing raw material output costs, reduction of waste and together, within the Altron Group, improve its carbon footprint impact. As EVS International’s distributor, Truth Electronics Manufacturing was paramount in the introduction of the innovative, award-winning EVS 7000LF Solder Recovery System to Altech.

EVS International recently completed a total redesign of the software and thermal insulation, resulting in a significant increase in recovery rates of up to 80 per cent by weight by improving the thermal efficiency and redesigning the software and mechanical solder path. These advances in thermal efficiency, software and mechanical efficiency lead to a significant reduction in carbon footprint and enhance EVS’ already high contribution to ISO 14001 [Recycle – Reduce – Reuse], adding to an already impressively fast return on investment (ROI).

The new High Solids Filtration System on the Lead-Free EVS 7000 dramatically increases air flow and dust/smoke capture, which is particularly important with some lead-free fluxes, while maintaining the small footprint of the new four-wheel steer cart with its pull-out service drawer. The system is complete with an LED monitoring system that shows a green light for normal running, an amber light when 75 per cent of the combination filter is used, and a red light when the combination filter should be changed — this in-house design is simplicity in itself to maintain with its built-in logic.

With its unique simplicity of operation and high recovery rates, the system provides fast payback and pure solder quality. The solder recovery system also improves the process by reducing shorts, bridging, and rework, significantly improving wave solder machine productivity, cleanliness and lowering pump maintenance and downtime. This package of benefits enhances the ability to attain and retain the corporate environmental standard, ISO 14001.

By using the newly-enhanced EVS system, users can benefit from up to 50 per cent significant savings in solder purchases. Additionally, users of Nitrogen can recycle their dross and turn down their Nitrogen by up to 60 per cent with the considerable savings this will bring.

According to Rajesh Ramkawal, Altech’s Operations Manager, “The increasing costs of Sn, has driven us to seek innovative ways in which to recover material from dross on our premises ourselves, rather than through external service providers. This acquisition has proven direct cost efficiency to us. The EVS solution demonstrated an extremely positive value proposition in enabling us to reach this objective. It has enhanced our environmental impact and cost efficiency as immediately as commissioned. We realised tangible payback within a few months of operating the EVS unit. It is a well industrialised piece of equipment, which can easily withstand the robust environment of production and maintenance in a high volume plant.”

London Metal Exchange, Tin Prices, 13 March 2011 - www.lme.com/tin.asp

Altech Case Study – Compiled by Rajesh Ramkawal, Altech’s Operations Manager

View and print Adobe PDF files

Free Adobe Reader® software lets anyone view and print Adobe PDF files. |

|

|